Manufacture of glass facing tiles

You can make glass tiles for wall cladding yourself, either plain (white, blue), or with an ornament or pattern. The area of ordinary ceramic tiles is 150x150 mm, this size is also suitable for homemade tiles.

But it would be better if you slightly increase the tile size, for example, to 200x200 mm. Firstly, larger tiles will be required for facing less (and there will be less work on their manufacture), and secondly, it is more convenient to make an ornament or a drawing that you like on large tiles. But the manufacturer has the last word in choosing the tile size.

The following tools will be needed to make tiles: glass cutter; template; foam tampons; awl; sandpaper (fine). You will have to purchase some materials: glass (3-4 mm thick); nitro paint and oil paint; river sand (coarse-grained).

Manufacture of facing glass tiles

First of all, they make a template according to which they will have to cut the tiles. Cover the glass cutting table with a cloth, strengthen the limiter on the left side of the table so that the glass does not move when cutting.

The thickness of the limiter is not less than 8 mm (2 thicknesses of glass), since the template superimposed on the surface of the glass must also rest against the limiter. It is better to cut the glass into squares with a diamond glass cutter.

The finished tiles need to blunt the sharp edges. Fill sandpaper on a small board and process the edges with this «file», after which the tile should be washed and dried. Next, it is best to work with tiles in small batches of 10-15 pieces.

Now let's choose the color in which the tile will be painted. Different options are possible. A light blue or blue ornament will be spectacular on a white background, and a white pattern on a light blue background.

The paint applied to the glass should dry quickly, so nitrocracks (nitroemals) are most suitable. Actually, the best for facing glass tiles is paint for road signs, as it is quite resistant to temperature changes and humidity.

So, you have chosen a color for the main background, for example, light blue. Estimate how much paint of this color will be required for the entire batch of tiles, since the paint should be enough for this entire batch, since it will be quite difficult to select the original color for the second time.

Fill a liter jar with paint, you will have enough for 35-45 tiles, that is, for 2-3 batches, close the dishes with the rest of the paint tightly and put them in a fireproof place.

Spread out 5-6 tiles on the table, pre-washed and dried. From a liter jar, pour a certain amount of paint into even smaller dishes and use a swab to apply paint from it to the glass.

The paint should be filled on the glass, only at the same time it lies on the surface with a smooth thin film. After covering the tile in this way and letting the paint dry, repeat the coloring. The paint should be filled on the glass with an even layer without gaps.

Having formed the background on a batch of tiles of 10-15 pieces, proceed to applying a pre-prepared pattern on them. Note that the drawing can be borrowed from a branded facing tile, or you can develop it yourself.

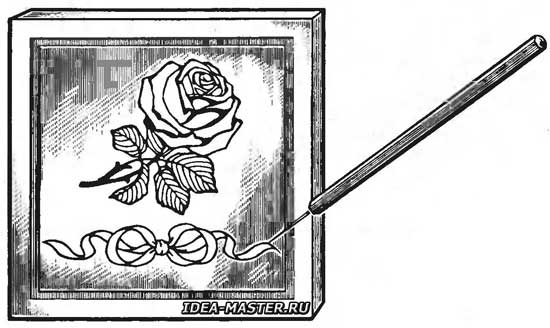

On the surface of the tile primed with paint, the selected pattern is translated or printed with water—soluble paints, for example, gouache, and then proceed to scratching the pattern - the most responsible work on which the quality of the tile will depend.

Scratching the outline of the drawing in the paint layer. |

Take an awl or a simple needle clamped in a collet pencil (the needle should protrude from the collet by 5-6 mm), and begin carefully scratching the paint along the contour of the applied pattern.

It is necessary to scratch the paint very carefully so that the glass is visible in the scratch-line, but so that the paint does not get up and crack. The paint layer is lifted up when the paint is not dry enough, and it cracks if it is dry. It is not recommended to work with tiles, the paint on which is applied 2-3 days before the start of «scratching».

After finishing work on the contour of one tile, it is lowered into water or covered with a wet cloth or paper, and then proceed to scratching the next tile.

After 15-20 minutes of «soaking», the tile is removed from the water and, without wiping or letting it dry, they begin to choose paint from the scratched contour. This operation is also performed with a needle or awl. If the tile is sufficiently soaked, then the pattern is removed with an even film without much effort.

In an evening, you can prepare 20-30 tiles, that is, more than 1 m². During the day, it is possible to make more than 3 m² tiles.

Well, and now the final part of the work follows — clogging the selected drawing with paint. As already mentioned, it is good to score a drawing on a light blue background with white or dark blue paint and vice versa. On a black background, it is better to cover the ornament with bronze.

Having painted over the drawing with the necessary paint, let the tile dry (up to 10 minutes) and «seal» both the background and the drawing with oil paint, applying it to the entire plane tiles. Meerkat is best suited for this, but other light-colored oil paints are also suitable. Now pour coarse-grained river sand over the paint soil and place the tiles vertically. The excess sand will crumble off the tile itself. After drying (2-3 days), the tile is finally ready for mounting on the wall.

In this way, it is easy to make a number on the door of your apartment: on a plate of glass primed with a background, scratch the apartment number in a mirror image. Further, all actions are similar to operations in the manufacture of tiles.

With smooth walls, the tile will fit well on any paint (except nitrocolor) with cement (cement is injected into the paint and the mixture is mixed until a paste-like mass is obtained.) Note that a 2-millimeter layer of paint cement holds the tile much stronger on the wall compared to cement mortar.

In the section «Repair and construction»

| Share this page on social networks: |